by Terrace Square Condominium Association

Since this 560-unit residential eight-building complex was constructed in two phases during the 1970s, many residents have reported leaking exterior walls in all buildings. Large areas of face brick at each building were observed to spall the exterior brick “crust.” A past history of deferred maintenance and a prior building investigation failed to address all sources of these widespread, persistent problems.

Since this 560-unit residential eight-building complex was constructed in two phases during the 1970s, many residents have reported leaking exterior walls in all buildings. Large areas of face brick at each building were observed to spall the exterior brick “crust.” A past history of deferred maintenance and a prior building investigation failed to address all sources of these widespread, persistent problems.

The condominium board consulted H|A|G to further investigate why the buildings continued to leak. Our team implemented strategies that included:

- A survey of the interiors of the 75+ units that continued to report problems, and assembly of work orders to immediately address items for homeowners that could receive short-term repairs quickly by on-site staff or maintenance contractors.

- Examination of the original construction drawings, past reports, and repair histories for the project.

- Performance of an overall visual inspection with standard high-resolution and thermal-imaging cameras, noting any broad patterns of distress for all buildings.

- An up-close, hands on inspection (by aerial lift) of all building facades in which all observable exterior defects for each building elevation were identified and digitally recorded. This included the sounding of approximately 250,000 face brick.

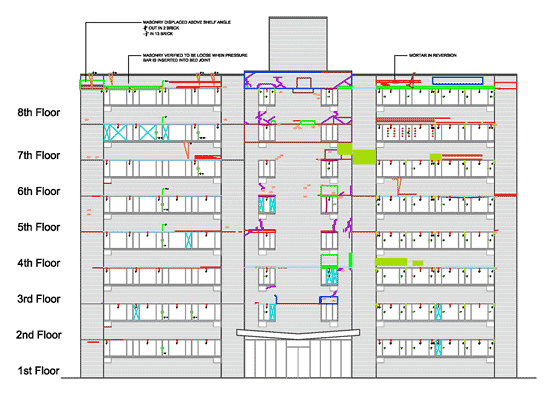

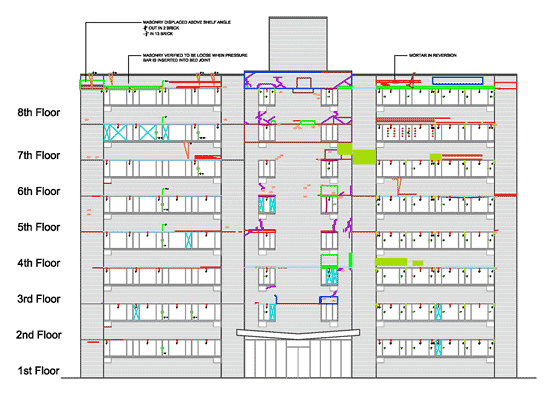

- The preparation of charted “Facade Distress Maps” for each building elevation, noting the exact location and quantity for each type of defect observed for the Owner’s records.

- The removal of face brick, digital recording of inspection openings at key suspect wall areasm and analysis of the results with a structural engineer.

- Laboratory testing of suspect masonry materials to evaluate their physical properties and continued suitability.

- Preparation of a comprehensive Condition Assessment Report of our findings to meet the highest industry standards of care for the owner.

Download PDF

by Terrace Square Condominium Association

As part of our inspection of Terrace Square Condominiums, a multi-floor test area of distressed exterior face brick was removed at one building for multiple reasons. The condition of the masonry was inspected by our team and digitally photographed to record the current construction of the wall. We observed a latent construction defect that created a common source point for water infiltration through walls of this type. Masonry materials were collected for laboratory testing, confirming that the original brick was sound.

As part of our inspection of Terrace Square Condominiums, a multi-floor test area of distressed exterior face brick was removed at one building for multiple reasons. The condition of the masonry was inspected by our team and digitally photographed to record the current construction of the wall. We observed a latent construction defect that created a common source point for water infiltration through walls of this type. Masonry materials were collected for laboratory testing, confirming that the original brick was sound.

With this information, our team (including consulting engineers from The Structural Shop) developed a prototypical method to match and most efficiently repair conditions of this type in future work for the buildings. Repair work involved replacing the existing multi-wythe header brick assemblies with standard running bond face brick set onto flashed steel shelf angles.

Balconies

As part of our investigation, we discovered that many resident balconies were originally designed in ways to allow water to prematurely age the precast concrete structures and steel guard rail assemblies and enter the buildings. Railings were found to violate current building code strength and picket spacing requirements.

After sounding the undersides of 270 balconies with visible distress, our team determined fifteen balconies to be imminently hazardous. These required demolition and the design of long-lasting replacement balconies to closely match the appearance of all the remaining balconies. For this, our work included:

- An investigation to determine the source points of balcony distress.

- The design for the replacement of deteriorated ornamental steel components and new code-compliant guard rails.

- The design for the replacement of concrete structural and non-structural components.

- The design of new sloped balcony topping slabs, to drain rainwater out and away from the building walls.

- The design of a new topside balcony waterproofing system and wearing surface.

- Construction observation services to monitor the quality of the repair work.

Download Masonry Case Study PDF

Download Balconies Case Study PDF

by Bristol Court Condominiums

Over 4,000 separate poor quality windows and spandrel panels were originally constructed without correct flashings, vapor barriers, and trim work for all 14 buildings of a suburban development. This allowed the intrusion of water, air-traffic noise, and lost valuable conditioned interior air, wasting energy. A prior 10-year-long $1,000,000 maintenance program failed to solve the problem.

Over 4,000 separate poor quality windows and spandrel panels were originally constructed without correct flashings, vapor barriers, and trim work for all 14 buildings of a suburban development. This allowed the intrusion of water, air-traffic noise, and lost valuable conditioned interior air, wasting energy. A prior 10-year-long $1,000,000 maintenance program failed to solve the problem.

H|A|G examined the window systems and their installation to determine the most correct method for replacement. Designs for multi-phased replacement were prepared, competitively bid and permitted. The contractor’s two-year replacement operations were routinely monitored to meet the highest industry standards of quality and to record the work for the owner’s records.

Download PDF

by Bristol Court Condominiums

An intense hail storm damaged all aging roofs of this suburban condominium complex of 14 four-story multi-residential buildings. The roofs could not be repaired. The insurer stipulated that the buildings be re-roofed for the budget of in-kind replacement to best match the original construction appearance from grade.

An intense hail storm damaged all aging roofs of this suburban condominium complex of 14 four-story multi-residential buildings. The roofs could not be repaired. The insurer stipulated that the buildings be re-roofed for the budget of in-kind replacement to best match the original construction appearance from grade.

HAG designed, bid, permitted, and administered the construction of the multi-phased roof replacement system for all buildings to the highest industry standards. This work included:

- A ±170,000 sq. ft. low slope, low albedo (reflectance) mechanically-fastened PVC membrane with a 15-year-material/5-year-labor warranty.

- Factory Mutual 4470 compliant impact resistance, hail damage resistance, wind uplift resistance and exterior fire resistance standards.

- Energy code compliant replacement insulation.

- High quality replacement drains for areas of heightened insulation for all roofs.

- The additional design of a ±90,000 sq. ft., 25-year-material/3-year-labor-warrantied cedar shake mansard replacement roof assembly.

Download PDF

by Balmoral Courts Condominiums, Timberlake Country Homes of Palatine

H|A|G performed similar work at two townhome complexes, including mitigation repairs to shingle roofs at 12 townhomes with irregular roof geometries. This included fixing original “latent defects” in the original construction, which caused premature aging of construction materials and water damage. For the five town homes at Balmoral Courts Condominiums, the damage was demonstrated to be so extensive as to warrant the replacement of all roofs with the correct detailing.

H|A|G performed similar work at two townhome complexes, including mitigation repairs to shingle roofs at 12 townhomes with irregular roof geometries. This included fixing original “latent defects” in the original construction, which caused premature aging of construction materials and water damage. For the five town homes at Balmoral Courts Condominiums, the damage was demonstrated to be so extensive as to warrant the replacement of all roofs with the correct detailing.

The Hicks Architectural Group’s work also included:

- Removal and replacement of poorly operating roof ridge vents, eave vents and “smart” vents.

- Removal and replacement of poor flashings for vent stacks and chimneys.

- Removal and replacement of deteriorated plywood roof sheathing with new fire rated plywood sheathing.

- Installation of additional modified bitumen roofing materials and flashings (in order to make weak portions of the roofs with irregular geometries watertight).

- Installation of additional waterproofing underlayment at eaves, skylights, chimney crickets, and valley flashings.

Download Timberlake Case Study PDF

Download Balmoral Case Study PDF

by 6300 N Sheridan Condominium Association

This condominium, built in 1964, experiences widespread leaking through the exterior masonry curtain wall, sagging masonry lintels and masonry step cracking.

This condominium, built in 1964, experiences widespread leaking through the exterior masonry curtain wall, sagging masonry lintels and masonry step cracking.

H|A|G was able to pinpoint 16 specific reasons for these problems, which were presented to the residents as part of an economical Facade Condition Assessment Report, meeting the highest industry standards of care. Our findings were obtained with the use of:

- Close up hands-on spot inspections (via swing stage scaffold) of east elevations & close up spot inspections (from Botswain’s Chair) of North, South and West Elevations.

- Collection and review of a comprehensive record of digital, high-resolution inspection images.

- Selection and review of inspection openings for representative, suspect masonry areas to verify the condition of the original construction.

- Preparation of charted distress “Facade Maps” for each building elevation, which located the exact location and quantity of each type of observed defect.

Download PDF

Since this 560-unit residential eight-building complex was constructed in two phases during the 1970s, many residents have reported leaking exterior walls in all buildings. Large areas of face brick at each building were observed to spall the exterior brick “crust.” A past history of deferred maintenance and a prior building investigation failed to address all sources of these widespread, persistent problems.

Since this 560-unit residential eight-building complex was constructed in two phases during the 1970s, many residents have reported leaking exterior walls in all buildings. Large areas of face brick at each building were observed to spall the exterior brick “crust.” A past history of deferred maintenance and a prior building investigation failed to address all sources of these widespread, persistent problems.

As part of our inspection of Terrace Square Condominiums, a multi-floor test area of distressed exterior face brick was removed at one building for multiple reasons. The condition of the masonry was inspected by our team and digitally photographed to record the current construction of the wall. We observed a latent construction defect that created a common source point for water infiltration through walls of this type. Masonry materials were collected for laboratory testing, confirming that the original brick was sound.

As part of our inspection of Terrace Square Condominiums, a multi-floor test area of distressed exterior face brick was removed at one building for multiple reasons. The condition of the masonry was inspected by our team and digitally photographed to record the current construction of the wall. We observed a latent construction defect that created a common source point for water infiltration through walls of this type. Masonry materials were collected for laboratory testing, confirming that the original brick was sound.

Over 4,000 separate poor quality windows and spandrel panels were originally constructed without correct flashings, vapor barriers, and trim work for all 14 buildings of a suburban development. This allowed the intrusion of water, air-traffic noise, and lost valuable conditioned interior air, wasting energy. A prior 10-year-long $1,000,000 maintenance program failed to solve the problem.

Over 4,000 separate poor quality windows and spandrel panels were originally constructed without correct flashings, vapor barriers, and trim work for all 14 buildings of a suburban development. This allowed the intrusion of water, air-traffic noise, and lost valuable conditioned interior air, wasting energy. A prior 10-year-long $1,000,000 maintenance program failed to solve the problem.

An intense hail storm damaged all aging roofs of this suburban condominium complex of 14 four-story multi-residential buildings. The roofs could not be repaired. The insurer stipulated that the buildings be re-roofed for the budget of in-kind replacement to best match the original construction appearance from grade.

An intense hail storm damaged all aging roofs of this suburban condominium complex of 14 four-story multi-residential buildings. The roofs could not be repaired. The insurer stipulated that the buildings be re-roofed for the budget of in-kind replacement to best match the original construction appearance from grade.

H|A|G performed similar work at two townhome complexes, including mitigation repairs to shingle roofs at 12 townhomes with irregular roof geometries. This included fixing original “latent defects” in the original construction, which caused premature aging of construction materials and water damage. For the five town homes at Balmoral Courts Condominiums, the damage was demonstrated to be so extensive as to warrant the replacement of all roofs with the correct detailing.

H|A|G performed similar work at two townhome complexes, including mitigation repairs to shingle roofs at 12 townhomes with irregular roof geometries. This included fixing original “latent defects” in the original construction, which caused premature aging of construction materials and water damage. For the five town homes at Balmoral Courts Condominiums, the damage was demonstrated to be so extensive as to warrant the replacement of all roofs with the correct detailing.

This condominium, built in 1964, experiences widespread leaking through the exterior masonry curtain wall, sagging masonry lintels and masonry step cracking.

This condominium, built in 1964, experiences widespread leaking through the exterior masonry curtain wall, sagging masonry lintels and masonry step cracking.